by L. S. Irish

Changes in moisture content

Over time any relief carving can warp, cup, or crack because of the natural stress caused by the changes in the humidity in the air and moisture content of the wood. Because wood is a natural product it absorbs and releases moisture with the changes of humidity in its surrounding environment, this means that the wood actually swells and shrinks with the changing seasons. That constant movement works against the weakest, thinnest points in your carving and adds stress to the joint lines.

Freshly cut wood, called green wood, is well saturated with natural moisture from its sap and resins. As soon as the wood is cut it begins to release that its moisture content with thin areas in the wood drying faster than thicker areas. The differing rates between the two thicknesses will cause a log or board to slip.

That same process can happen in our relief carving boards even though the wood has already been dried, either by quick low temperature kiln firing or by air drying where the boards are stacked allowed to dry over a long period of time, often years.

Thin backgrounds warp under stress

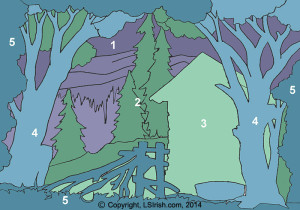

The deeper you carve into the wood the thinner the background wood becomes which weakens its ability to support the wood’s original flat shape when placed under the stress of environmental humidity changes.

So as a general rule your relief carving should fall in the top one-half thickness of your board. For a 3/4″ board the main areas of carving will be in the top 3/8″ or for a 2″ thick slab the carving is done in the top 1″ area.

If you are not planning any extremely steep level changes in your work as a drop from the original level of the wood directly into the deepest point of your background you can carve a little deeper. Gradual drops in the carving through the levels do not place as much stress as steep plunges in the overall work.

Extra carving depth in extra thick slabs

If you are working on an extremely thick slab, 3″ or more, you can again allow the carving to go deeper than the one-half rule since 1 1/2″ to 2″ of background wood often has enough thickness on its own to support the carving.

|  |

|  |

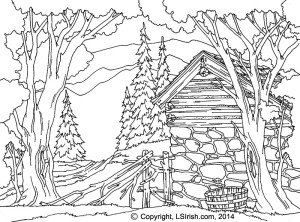

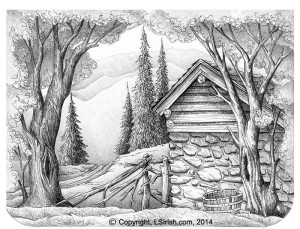

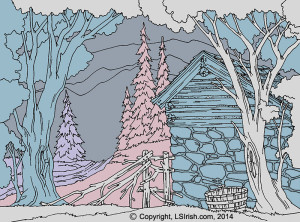

Click on the patterns above for a full-sized pattern.